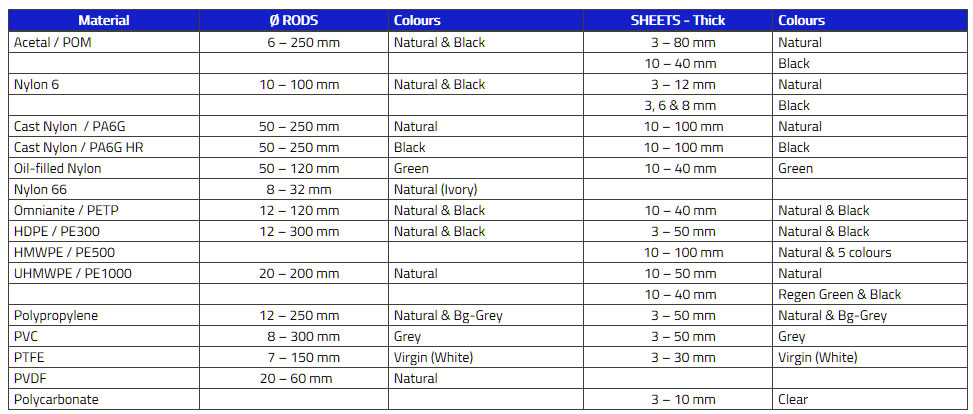

Omniacetal (Acetal / POM)

- Good sliding properties, high surface strength and rigidity, low moisture absorption, great dimensional stability

- Resistant to alkali and organic compounds

- It is very easy to machine and offers an excellent surface finish

- Our black and natural POM is Food Safe

- Uses include bearings, guides, gear wheels, fittings, valve and pump components

Omniamid 6G (Cast Nylon Natural)

- Very good wear resistance, even in demanding environments

- It is slightly tougher and harder than the extruded nylon 6

- Like all nylons it is hygroscopic (absorbs moisture) so it has poor dimensional stability

Omniamid HR (Cast Nylon Black)

- The addition of graphite and special lubricant results in properties better than those of the above natural PA6G

- Lower friction coefficient and higher shock resistance

- Applications include large gears, pulleys, sheaves, wheels, rollers, sliding blocks, guides. Resistant to alkali, solvents and inorganic compounds

Omniamid OIL (Green Oil-

- Contains 6% special lubricating oil

- The unique method of production results in micro distribution of the oil particles which is homogenous

- Lowest friction coefficient of all these nylons

- Higher shock resistance and better wear properties

Nylon 6

- This extruded nylon offers a combination of mechanical strength, stiffness, toughness, damping properties and wear resistance

- Omnia Plastica use a high viscosity polymer which results in a product of outstanding quality

- Natural nylon 6 is Food Safe

Nylon 66

- Nylon 66 is more rigid/harder than Nylon 6 and it is much easier to machine on Swiss & Cam automatics

Omnianite (Polyester / PETP)

- Low friction coefficient. High mechanical strength, stiffness and hardness with good creep resistance

- Excellent wear resistance (equal to nylon 6)

- Better resistance to acids than nylon and acetal

- Excellent bearing & bushing material

- Like acetal it is very easy to machine

- PETP is Food Safe

HDPE / PE300: High Density Polyethylene

- Good chemical resistance to acids, detergents and hot water

- Very good impact strength and excellent wear resistance, even at low temperatures

- Low friction coefficient

- Food Safe

HMWPE / PE500: High Molecular Weight Polyethylene

- Mol. weight 500,000

- Good chemical resistance and better impact strength than HDPE

- Good electrical insulating properties

- Used for guides, rollers, chopping blocks

- Available in 5 colours, all Food Safe

UHMWPE: Ultra High Molecular Weight Polyethylene

- PE1000. Mol. weight 5 mil. PE8000 mol. weight 9 mil

- Good chemical resistance

- Excellent abrasion resistance, Superior impact strength and very low friction coefficient

- Operates at temperatures as low as -

200⁰C. PE1000 is widely used in conveyors, bottling and packaging machines - PE8000 is a premium grade lining material, used in heavy duty material handling (eg dump trucks, hoppers, chutes and silos)

- Virgin material is Food Safe

Polypropylene

- High mechanical and tensile strength but low notched impact strength

- Brittle at low temperature. Withstands attack by alkali and acids

- Food Safe

- Used in pumps, valves, tank fabrication, flanges, bushes

PVC

- Flame retardant plastic with excellent chemical resistance, high mechanical strength and low stress cracking

- Poor impact strength

- Used for pump and valve bodies, tank fabrication, galvanic industry

PTFE (Teflon®)

- Best chemical resistance, lowest friction coefficient and high temperature range (-

200⁰C + 260⁰C) - Good dielectric strength

- Excellent weather resistance and insensitive to UV rays

- Poor mechanical properties. Food Safe (non-

toxic) - Used for O-

rings, valve seats, stem seals, gaskets, insulators, guides, bellows

PVDF

- Better tensile strength, mechanical strength and dimensional stability than PTFE

- Excellent chemical resistance and good temperature range (-

30⁰C +150⁰C) - Food safe (FDA compliant) and has a UL94 flammability rating of V.0

- Used as flanges as well as pump and valve components

Standard Stock